J D Global Trading Company provide a level of quality Electroplating Molybdenum, Electroplating Tungsten, Electroplating non-ferrous metals over the past years. Molybdenum and Tungsten are non-ferrous metals. Why we can electroplating molybdenum, electroplating tungsten, electroplating non-ferrous metals due to we have high tech equipment, skill, and knowledge on electroplating area.

In the specialized microwave industry, consistency in plating precision parts which are made to exacting specifications is a day to day reality. From large microwave housings to the tiniest components, we offer gold, silver and rhodium finishing on small, large and very large parts in the industry.

We also provide customers over the past years below service.

Electroplating Service:

We are certified suppliers to many leading companies throughout the world. Our electroplating finishes in gold, platinum, palladium, rhodium, and ruthenium...etc, can be custom plated to meet just about any decorative, experimental, medical, industrial application, or microelectronic application. In addition, the expert staffs at J D. have a great deal of technical and practical experience in all aspects of metal fabrication, repair, reconstruction and precision electroplating on ferrous and nonferrous objects and surfaces. We offer premier quality services with exceptional attention to detail. Total quality management is our philosophy. Continuous quality improvement is our goal.

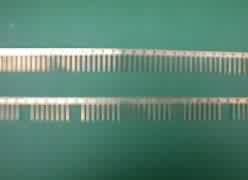

Precision Stamping Service:

Base metal and precious metal stampings to meet a wide variety of electrical and mechanical applications. Semiautomatic and hand assembly operations offer cost-effective alternatives for intermediate volume applications that cannot support the high cost of full automation. Low volume buss bar assemblies for high voltage power applications to multi-piece metal and plastic staked assemblies are produced to customer specifications.

Brazed Contact Assemblies Service:

Solder brazed contact assemblies for heavy-duty electromechanical and other special applications. Furnace brazing, flame brazing and resistance brazing and welding techniques provide high-quality liquid phase bonds. Our staff of product engineers, tool & die designers and manufacturing engineers provides technical support in the areas of part design and applications engineering. We can help you with the design of parts that are well-suited to economical manufacturing processes. Although we have already developed many innovative manufacturing techniques, we constantly develop new technologies to provide our customers with the best part or assembly at the best price.