Molybdenum Copper alloy is the composite material of Molybdenum and Copper. It has the similar performances as Tungsten Copper alloy. But its density is less than Tungsten Copper alloy’s, so it is more suitable for spaceflight and navigation industries.

J D Global Trading Company has been providing customers over the past years with the most advanced hermetic connector and packaging technologies available to provide a controllable expansion composite matrix, yielding superior material stability and uniform thermal expansion characteristics to provide the designer a practical solution to meet critical thermal parameters.

Advantages of Molybdenum Copper (MoCu):

Thermal expansion can be design; High thermal conductivity; Precision flatness capability; Bondable gold plating; Thickness from .004" to .500"; Zero corner radius; Integrated ribs; Precision complex geometry; Low thermal expansion; Good electrical conductivity; High wear resistance; More lighter than W-Cu.

Typical Physical and Mechanical Properties:

| Material Composition | Density (g/cm3) | Thermal Conductivity W/moK 25°C | Coefficient of Thermal Expansion 10-6/°C |

| 85Mo/15Cu | 10.01 | 195 | 7.0 |

| 80Mo/20Cu | 9.96 | 204 | 7.6 |

| 70Mo/30Cu | 9.75 | 208 | 8.0 |

| 60Mo/40Cu | 9.62 | 223 | 9.3 |

| 50Mo/50Cu | 9.51 | 230 | 10.3 |

Typical areas Application:

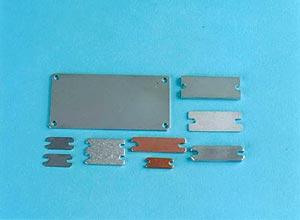

- Heat Sinks and Spreaders

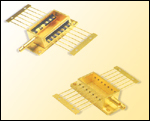

- Microwave Carriers

- Microelectronic Package Bases and Housings

- Ceramic Substrate Carriers

- GaAs and Silicon Device Mounts

- Laser Diode Mounts

- Surface Mount Package Conductors

- Microprocessor Lids

- Rocket Parts

- Optical Packages

- Power Packages

- Butterfly Packages